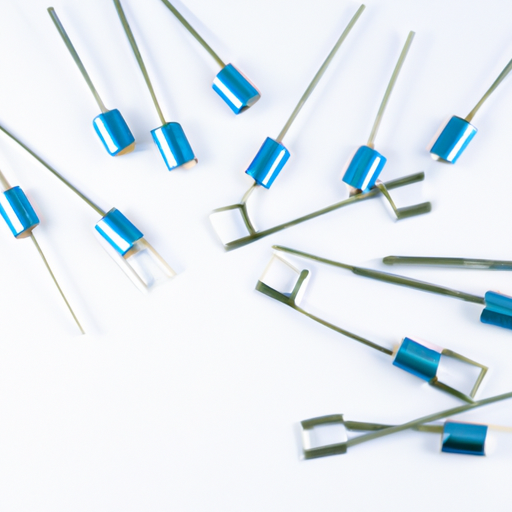

Core Functional Technology of NTC Thermistors

1. Temperature Sensitivity: NTC thermistors, such as the CFR-50JB-52-1K8, are designed to exhibit a significant change in resistance with temperature variations. This sensitivity allows for precise temperature measurements, making them suitable for applications that require accurate thermal readings.

2. Resistance-Temperature Characteristics: The relationship between resistance and temperature in NTC thermistors can be mathematically described using the Steinhart-Hart equation or the beta parameter equation. This characteristic enables the creation of detailed temperature-resistance curves, which are essential for calibration and accurate temperature sensing in various applications.

3. Fast Response Time: NTC thermistors respond quickly to temperature changes, which is crucial for applications that require real-time monitoring and control. This rapid response ensures that systems can react promptly to thermal fluctuations, enhancing overall performance.

4. Compact Size: The small form factor of NTC thermistors allows for easy integration into a wide range of devices. Their compact size makes them ideal for applications where space is at a premium, such as in portable electronics or tightly packed machinery.

5. Cost-Effectiveness: NTC thermistors are generally more affordable than other temperature sensing technologies, such as RTDs (Resistance Temperature Detectors) or thermocouples. This cost-effectiveness makes them a popular choice for manufacturers looking to balance performance with budget constraints.

Application Development Cases

1. Consumer Electronics: In consumer electronics, NTC thermistors are commonly used for temperature monitoring in devices like smartphones, laptops, and gaming consoles. For instance, they help manage battery temperatures to prevent overheating, thereby enhancing safety and prolonging battery life.

2. HVAC Systems: NTC thermistors play a vital role in HVAC systems by monitoring the temperature of air and refrigerants. They help optimize system performance, improve energy efficiency, and maintain comfortable indoor environments by providing accurate feedback for temperature control.

3. Automotive Applications: In the automotive sector, NTC thermistors are integral to engine temperature monitoring, cabin climate control, and battery management in electric vehicles. Their reliability and precision are essential for ensuring vehicle safety, performance, and efficiency, particularly in electric and hybrid vehicles where thermal management is critical.

4. Medical Devices: NTC thermistors are widely used in medical devices, including digital thermometers, incubators, and patient monitoring systems. Their high accuracy and fast response times are crucial for providing reliable temperature readings in critical care settings, where even slight deviations can have significant implications.

5. Industrial Automation: In industrial environments, NTC thermistors are employed for monitoring the temperature of machinery and processes. They help prevent overheating, ensure optimal operating conditions, and enhance equipment longevity, contributing to improved efficiency and reduced downtime.

6. Home Appliances: NTC thermistors are utilized in various home appliances, such as refrigerators, ovens, and washing machines, for temperature regulation. They ensure that appliances operate efficiently, maintain optimal performance, and contribute to energy savings by accurately controlling heating and cooling cycles.

Conclusion

The CFR-50JB-52-1K8 NTC thermistor exemplifies the core functional technology of NTC thermistors, characterized by high sensitivity, rapid response times, and cost-effectiveness. Its diverse applications across industries such as consumer electronics, HVAC, automotive, medical devices, industrial automation, and home appliances highlight the versatility and reliability of NTC thermistors. As technology continues to evolve, the role of NTC thermistors in enhancing performance, safety, and efficiency in various applications will remain significant, making them a critical component in modern electronic systems.