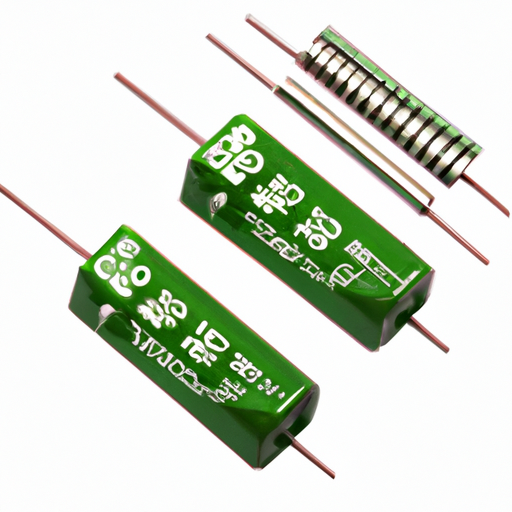

Core Functional Technologies of Film Capacitors

1. Dielectric Material: Film capacitors utilize thin plastic films as the dielectric material, which can be made from various polymers such as polyester (PET), polypropylene (PP), and polycarbonate (PC). The choice of dielectric affects the capacitor's performance, including its voltage rating, capacitance stability, and temperature coefficient. For instance, polypropylene is known for its excellent thermal stability and low dielectric losses, making it ideal for high-frequency applications.

2. Low ESR and ESL: Film capacitors typically exhibit low equivalent series resistance (ESR) and equivalent series inductance (ESL), making them suitable for high-frequency applications. This characteristic allows for efficient energy storage and minimal energy loss, which is crucial in applications like RF amplifiers and switching power supplies.

3. High Voltage Ratings: Film capacitors can handle high voltage applications, making them ideal for power electronics, motor drives, and other high-voltage circuits. Their ability to withstand high voltages without failure is essential in applications such as power inverters and industrial machinery.

4. Temperature Stability: Film capacitors maintain their capacitance over a wide temperature range, providing reliable performance in varying environmental conditions. This stability is crucial for applications in automotive, industrial, and aerospace sectors, where temperature fluctuations can be significant.

5. Self-Healing Properties: Many film capacitors possess self-healing capabilities, meaning that if a dielectric breakdown occurs, the capacitor can recover without permanent damage. This feature enhances reliability and longevity, making film capacitors suitable for critical applications where failure is not an option.

6. Low Leakage Current: Film capacitors have very low leakage currents compared to electrolytic capacitors, making them suitable for applications where energy efficiency is critical. This characteristic is particularly important in battery-operated devices and energy storage systems.

Application Development Cases

1. Power Electronics: In power supply circuits, film capacitors are used for filtering and energy storage. Their low ESR and ESL characteristics help in smoothing out voltage fluctuations, improving the overall efficiency of power converters and inverters. For example, in a solar inverter, film capacitors can enhance the performance by reducing ripple voltage and improving power factor.

2. Audio Equipment: High-fidelity audio systems often utilize film capacitors for coupling and bypass applications. Their low distortion and high-frequency response contribute to superior sound quality, making them a preferred choice for audiophiles. In high-end audio amplifiers, film capacitors are used in the signal path to ensure clarity and fidelity.

3. Motor Drives: In variable frequency drives (VFDs), film capacitors are employed for DC link applications. Their ability to handle high ripple currents and voltages ensures stable operation and enhances the performance of electric motors. This is particularly important in industrial automation where precision and reliability are paramount.

4. Renewable Energy Systems: Film capacitors are increasingly used in solar inverters and wind turbine converters. Their reliability and efficiency help in maximizing energy conversion and storage, contributing to the overall effectiveness of renewable energy systems. For instance, in a solar power system, film capacitors can improve the efficiency of the inverter, leading to better energy harvest.

5. Automotive Applications: With the rise of electric vehicles (EVs), film capacitors are used in battery management systems (BMS) and power electronics. Their robustness and thermal stability are essential for the demanding conditions in automotive environments. In EVs, film capacitors can help manage power distribution and improve the efficiency of electric drivetrains.

6. Telecommunications: In communication systems, film capacitors are used for signal coupling and decoupling. Their high-frequency performance and low noise characteristics are critical for maintaining signal integrity in high-speed data transmission. In 5G networks, for example, film capacitors play a vital role in ensuring reliable signal processing and transmission.

Conclusion

The CFR-50JB-52-1K1 film capacitor exemplifies the advanced technology and versatility of film capacitors in various applications. Their unique properties, such as low ESR, high voltage ratings, and self-healing capabilities, make them indispensable in modern electronic designs. As technology continues to evolve, the demand for reliable and efficient capacitors will only increase, further solidifying the role of film capacitors in the electronics industry. The ongoing development of new materials and manufacturing techniques will likely enhance the performance and applicability of film capacitors, ensuring their relevance in future innovations.